BACKGROUND

In the manufacturing industry, a leading company faced challenges in maintaining competitiveness and delivering value. The existing communication processes and cycle times required improvement to stay ahead. Notable concerns included inefficient tooling, inserts, holding capability, and CNC programs for newly acquired products.

SOLUTION

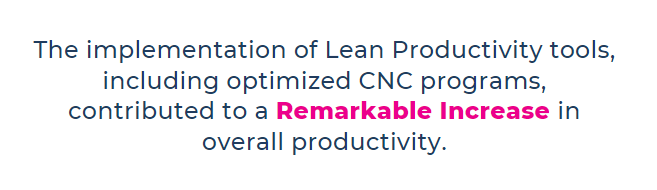

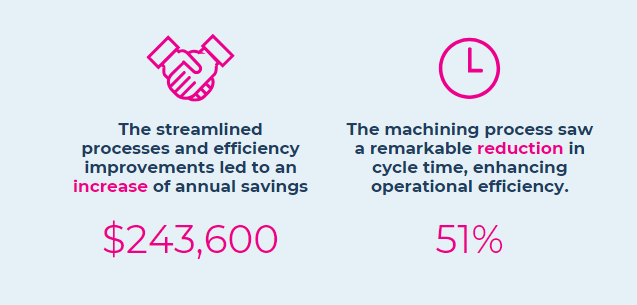

Working with our team of Digital First Facilitators, with a focus on fostering improved communication, addressing tooling inefficiencies, and streamlining machining processes – including the implementation of Huddle Boards and an improved communication culture that would prove to be transformative.

OUTCOMES

- Morale Improvement: The introduction of Huddle Boards and a new communication culture positively impacted employee morale.

- Defect Reduction: The streamlined processes resulted in a significant reduction in defects, enhancing product quality.

- Enhanced Equipment Utilization: The optimized tooling and inserts, along with improved holding capability, led to better equipment utilization.